Competing on the World Market by Integrating Technology and Crop Management: Cotton in Australia

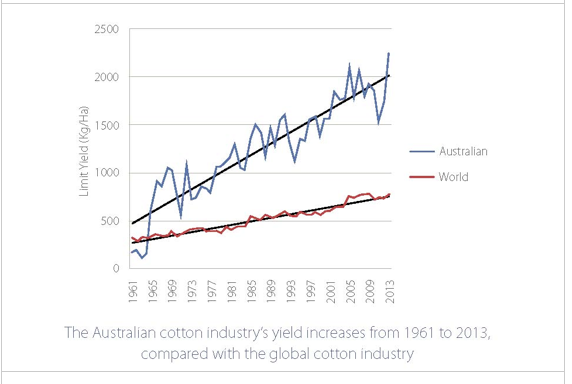

Australian cotton crops now produce yields of around two and a half to three times world averageand Australian cotton yields are the highest in the world.

This is largely because of the rapid adoption of new technologies, but also because much of the crop is irrigated compared with many overseas countries where extensive areas of raingrown cotton are produced.

This remarkable story has been one of concerted interest and investment in research development and extension (RD&E), and an industry-wide effort to embrace new technology.

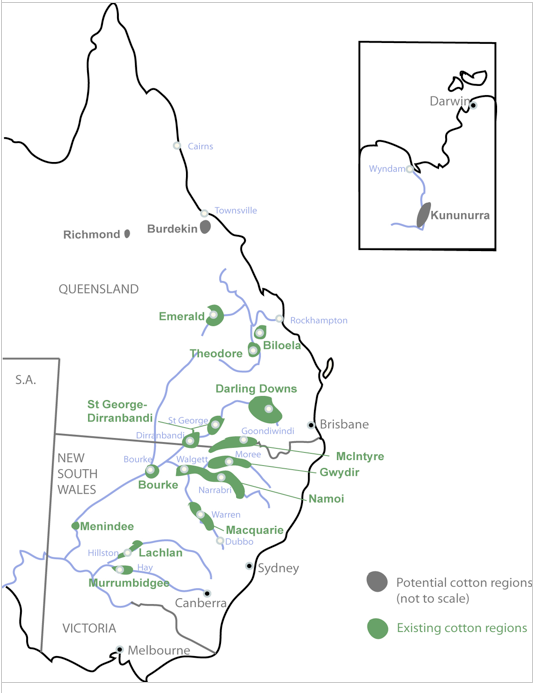

The modern industry based on irrigated production has grown to over $2 billion in exports (five year average between 2009 and 2014; Source: Cotton Australia) and the main production areas have extended north of Emerald and south of the Macquarie River as production technologies have improved. Cotton became Australia’s fourth largest rural export, but the 2014 drought relegated it to ninth (ABARES 2015).

This paper elaborates on the successes and failures from the 1970’s to 2016. This is the story of the modern Australian cotton industry although we should acknowledge that cotton has been a part of Australian agriculture for over 100 years.

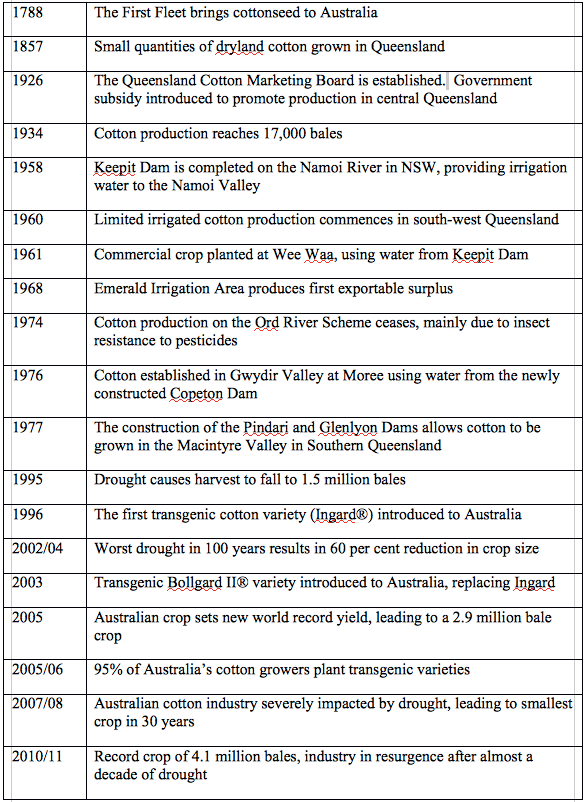

Table 1 summarises the history of cotton production in Australia (Source: Cotton Australia).

1973-74 marked a turning point in the Australian cotton industry. Cotton production ceased in the Ord Irrigation area, largely because of insect pest resistance to pesticides, and the industry was gaining strength in northern NSW and Queensland.

Irrigated crop production in the St George region of Queensland was developing and Fairbairn Dam in central Queensland had its first fill of water. About two thirds on the national crop was grown in NSW and about one third grown in Queensland.

During the 1960s, “modern” cotton production systems, were pioneered in northern NSW by the Kahl and Hadley families from California, and by the Brimblecombe and Armstrong families in southern Queensland. This was large-scale, irrigated production, and from the outset, the pioneers of the modern cotton industry had a focus on RD&E.

The Australian Cotton Growers Research Association (now incorporated within Cotton Australia) was formed and became a very forward-thinking group of growers and ginning organisations who supported a research program centred at Myall Vale (near Narrabri) and engendered collaboration across the entire industry.

Some of the leading research scientists, originally based in the Ord Irrigation Area were enticed to Myall Vale and ultimately made an enormous contribution to the Australian and World cotton industry.

This RD&E effort was underpinned by investments through the Cotton R&D Corporation and three successive Cooperative Research Centres (CRCs) from 1994 to 2012. (Cunningham and Jones, 2012). NSW Agriculture, Queensland DPI, CSIRO, UNE, Sydney University and CRDC were core participants from the outset, although the focus changed from Sustainable Cotton Production, through Australian Cotton to Cotton Catchments and Communities.

This story of success has not come without challenges. Improved crop varieties and improved fibre quality, integrated pest management, advances in weed management, reduced environmental impacts, irrigation water use efficiency, and improved farming systems all contributed to the gains in yield performance.

Droughts and floods have also had an impact and the recent drought caused a severe reduction in area cropped to cotton.

The modern Australian cotton industry is largely irrigated, and the crop is mostly grown on vertisols, the cracking clay soils found on the flood plains of the Fitzroy, Condamine-Balonne and Border Rivers of Queensland and the Gwydir, Namoi, Macquarie, Darling and Murray Rivers of NSW.

Recently, cotton production has expanded to the Lachlan and Murrumbidgee rivers in southern NSW and cotton has the potential to be grown again in northern Australia.

Yield Performance

Australian cotton yields have grown from around 500 kg per hectare (2 bales per hectare) in the early 1960s to over 2000 kg per hectare (8.8 bales per hectare) in 2013 as a national average as shown in figure 2.

We might ask “where will this end?” Are we near the physiological limit for cotton crop yields? The 2015 and 2016 harvests have seen individual farm yields exceed 15 bales per hectare, so we still have room for improvement in national averages.

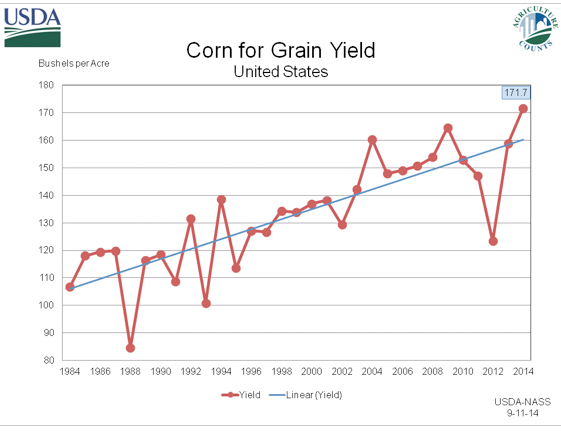

The Australian cotton yield performance is exceptional, but not unique. Corn yields in the US have likewise grown from around 100 bushels per acre (6.25 tonnes per hectare) to 170 bushels per acre (10.7 tonnes per hectare) from 1984 to 2014. See Figure 3.

Where does this yield improvement come from? Constable (2004) explained the yield gains for irrigated cotton as being partly due to improved varieties (45%) improved soil and water management (25%) improved insect management (20%) and better disease management (10%).

Since this paper was written, the Australian cotton industry has almost universally adopted GM cotton technologies. The Bollgard genes and the genes for resistance to the herbicide glyphosate (Roundup Ready) have enabled the industry to further enhance yields. Improvements in lint quality have also enabled the base grade for Australian cotton to be lifted another level.

In many ways, Australia’s cotton breeders have led the world in developing high quality, disease tolerant, herbicide resistant, insect resistant high yielding varieties. Australian cotton varieties have been so successful that they are now grown in the United States and elsewhere (under license).

In the 1970s cotton varieties were largely imported from the United States. Deltapine 16 was a common variety and it was superseded by Deltapine 61 and then Deltapine 90.

These varieties were better performing than their predecessors, but were susceptible to Verticillium Wilt (a serious disease of cooler regions), Bacterial Blight (prevalent in hotter regions) and of course offered little or no resistance to insects.

In 2016, Bollgard 3 RoundupReady varieties were launched commercially and commercial production of this latest suite of varieties was widely and comprehensively adopted in 2016-2017 season.

According to Monsanto, in their 15 December 2016 Newsletter, Australian cotton farmers planted 92 per cent of the 2016-2017 season’s 457,000-hectare crop to varieties containing the new technology. This shows remarkable confidence in the new technology and a propensity of Australian cotton farmers to rapidly adopt new beneficial technologies.

This follows the very successful Bollgard II RoundupReady varieties and the industry anticipates these new varieties will provide a more robust insect resistance management tool for Australia cotton growers.

Adding to the Bt proteins found in Bollgard II, (Cry1Ac and Cry2Ab), Bollgard 3 will also include a third Bt protein Vip3A. These three proteins will increase the longevity of the technology, each having a different mode of action or ‘killing’ larvae in a different way (Monsanto 2016).

Early results indicate that Bollgard 3 is highly effective against Helicoverpa species, but it is too early to determine how the technology will affect any future Resistance Management. (Monsanto.com, 2016)

But the GM traits are only part of the story. Over the years, resistance to Verticillium Wilt, Bacterial Blight and Fusarium Wilt has been enhanced in successive commercial variety releases.

Fibre quality has been enhanced substantially, with stronger, longer finer fibres that suit the requirements of modern spinning mills. Varieties with higher ginning outturns have also enhanced returns to growers. (Constable et al. 2011).

Pest Management

Cotton crops are very attractive to insect and mite pests and effective Integrated Pest Management (IPM) has been a goal for the industry for decades.

At times, over 60% of the total investment in RD&E by CRDC has been on IPM and only recently, with the introduction of GM cotton has the industry been able to achieve real reductions in pesticide use.

From 1998-1999 when the average application use of insecticide was about 12 kg of active ingredient per hectare the industry now uses less than one kg per hectare of active ingredient.

Spraying for the two major Helicoverpa spp. pests (H. armigera and H. punctigera), previously known as Heliothis spp, has decreased by almost 100 per cent.

The main pests requiring treatment are now sucking pests including: silverleaf whitefly, cotton aphids, mirids (predominantly green mirid), mites, and green vegetable bug. (Wilson et al. 2013)

Two main factors at play in the IPM story have been the propensity of Helicorverpa spp species to develop insecticide resistance and the heavy use of insecticides resulting in the ecological balance within the crop favouring the pest species.

This was apparent in the experience of the Ord Irrigation Area with respect to insect management, and the cotton industry failed to learn the lessons for the following decades. According to reliable reports, in excess of thirty sprays were used to control insect pests when they were at their worst. Farmers on the Darling Downs and elsewhere used over 25 sprays for the 1972-73 season.

At that stage, DDT was the main insecticide used, and it was used in combination with endrin and methyl parathion to control the range of pests experienced. Later, chlorcam was added to the DDT because of the resistance developed by H. armigera.

This heavy insecticide use was ecologically damaging, it earned the cotton industry a reputation of being environmentally irresponsible, and of course, was expensive for the farmer. Induced pests (secondary pest outbreaks) became serious problems as well, and spider mites for example, often required additional insecticide treatment as the season progressed.

To add to these challenges, the insecticides used by cotton farmers found their way into livestock, initially DDT, then chlorflurazuron (Helix) followed by endosulfan. The cotton industry was no longer a “good neighbour” for livestock producers.

The early efforts in IPM were only partly successful, but the investment in understanding the pests, their relationships with the host (cotton) their ecology within the farming system and the use of this knowledge by farmers and their consultants have led to a much better situation now.

In Queensland, some of the earliest field studies on unsprayed cotton were conducted by a visiting professor from Texas A&M University, Winfield Sterling.

The Lockyer Valley crop was severely damaged by pests, but cotton pest sampling techniques were developed and the concept of beneficial insects promulgated to the industry.

Shortly after this, Peter Twine released a parasitic wasp, Trichogramma spp. in an isolated cotton field at St George, with the purpose of increasing the prevalence of beneficial insects to control Heliocoverpa spp. This also was only partially successful.

Although these attempts to control Helicorverpa spp. were insufficient to prevent significant crop damage, understanding of the pest species was improving.

The two main species of Helicorverpa could be identified anatomically, and it was clear that H. armigera was the species which developed resistance to insecticides and this species became harder to control later in the season.

H. armigera went into diapause in the soil in the regions of the Darling Downs and farther south, enabling the pest to carry genes for resistance from season to season.

Later in the 1970s pyrethroid insecticides became available and were promoted as a “saviour” for the cotton industry’s pest problems.

Despite warnings from professional entomologists, the companies who marketed pyrethroid products, promoted the use of these insecticides heavily, and predictably, in 1983 high levels of pyrethroid insecticide resistance were recorded at Emerald, and then elsewhere throughout the cotton industry, (Daly, J.C. and Murray, D.A.H. 1988)

Crops that had been sprayed a number of times could be infested with scores of H. armigera in every square metre. Although not fully understood at the time, the pyrethroid insecticide applications destroyed the beneficial insects and failed to kill the pests. This then enabled the pests to build up to extraordinary populations.

At about this time, the cotton industry invested in a program SIRATAC, which provided a sampling routine and common basis for economic spraying thresholds for the industry.

This computer-based decision support system used algorithms to predict likely insect pest damage and although not used by consultants universally, it provided great impetus for thorough pest sampling and an acknowledgement that sampling for pests alone was insufficient to enable sound pest management systems.

Beneficial arthropods were important as was the ability of the cotton plant to compensate for damage.

New IPM strategies evolved. These were principally centered on delaying the use of broad-spectrum insecticides until late in the season and attempting to reduce the problem of secondary pest outbreaks.

This led to the insecticide resistance management strategy (IRMS) being developed. We now had resistance to the organochlorines in the early 1970s, pyrethroids in the 1980s, and carbamates in the 1990s. Crops were still being sprayed 12 to 16 times (Wilson et al. 2013). Some of the insecticides were clearly environmentally hazardous and expensive to use.

During this time our understanding of pests and their natural enemies had developed. We now understood that H. armigera developed resistance to insecticides because it reproduced within the local farming system ensuring successive generations of the pest were exposed to insecticide treatment, enabling the selection of resistant populations. (Scott et al. 2005).

On the other hand, H.punctigera populations were diluted by immigration of large populations of moths from central Australia. This diluted the genes for insecticide resistance.

This new understanding led us to the concept of Area Wide Management. If resistant populations were being generated within the local cropping system, it was here the resistant population must be managed. (Scott et al. 2005).

At the same time, the impact of using broad spectrum insecticides such as pyrethroids on beneficial insects became apparent. We were creating our own problems in both development of insecticide resistance and removing any natural controls offered by the environment. (Murray, D et al. 1996).

Crop consultants became almost universally used by cotton growers. Their professionalism and engagement in RD&E has facilitated the rapid adoption of IPM practices. Their participation in and development of insect pest management strategies was a key factor in the industry being able to manage pest problems.

Integrated Weed Management

The cotton crop is very sensitive to weed competition, particularly in its early growth stages.

Various strategies for weed control have been used, but most notably, the dinitroanalines (trifluralin and similar herbicides) were used for selective grass weed control and diuron, fluometuron, and prometryne for selective broad-leaf weed control. Inter-row cultivation was used universally, often with three or more passes to remove weeds in the inter-row space.

Despite these control measures, weeds were still a problem within the crop row and cotton chippers were used extensively.

This provided a work opportunity for local members of cotton communities, but the work is hot and difficult and proved challenging to manage. Chippers had to be employed in fields after inter-row cultivation and before the next irrigation and care had to be taken to ensure chippers were not unnecessarily exposed to insecticides.

The herbicides used were not totally selective. Trifluralin caused root pruning and required thorough incorporation which meant dry soil conditions at herbicide application time. The other herbicides such as diuron and fluometuron caused crop damage if rain fell shortly after planting.

In this situation, the herbicide was usually applied post-plant, pre-emergence and heavy rainfall could concentrate herbicide near germinating seedlings. (Hamilton, W. D. and Hazard, W. H. 1981).

Inter-row cultivation also was detrimental to crop performance, drying the soil and disturbing the roots of the growing crop. Other herbicides such as MSMA were applied for difficult-to-control weeds such as noogoora burr.

This herbicide régime was expensive and some of the herbicides found their way into the environment, mainly water courses downstream of cotton farms.

The glyphosate-tolerant “RoundUp Ready” varieties solved many of these problems. Two or three in-crop applications of glyphosate controlled almost all weed problems and many farmers were able to eliminate inter-row cultivation as well.

However, the widespread use of glyphosate has generated another problem, that of herbicide-resistant weeds. Because glyphosate is also widely used as a fallow spray in both irrigated and dryland cropping systems, the problem is likely to worsen.

For this reason, consultants and farmers have implemented strategies to slow the development of herbicide resistance and new herbicide chemistries are being developed.

Water Use Efficiency

Irrigation water use efficiency has been important for the cotton industry for decades, but it was not until the 1990s that water availability became a major concern and water restrictions were being placed on irrigators.

Farmers believed that their water use practices were efficient until Tennakoon and Milroy (2003) measured on-farm water efficiency on 25 farms over the period 1996-97 to 1998-99.

Their study revealed an average farm irrigation efficiency of 57% with large variation between properties. They observed irrigation efficiencies ranging from 25% to 80%.

This established the need for further research and farmers renewed their commitment to use irrigation water efficiently. This study built on work by Cameron and Hearn, (1997).

Subsequently, the Irrigation Futures CRC was established and a group at the University of Southern Queensland established improved ways of measuring and managing irrigation water use.

With better instrumentation and a focus on irrigation scheduling, industry practices have now changed. A much-improved knowledge of soil properties also enhanced management capability.

For example, in the 1980s and 1990s most scientists and farmers believed that the vertisols, on which cotton is mostly grown, were showing very little deep drainage.

Silburn and Montgomery (2004) and others clearly demonstrated that deep drainage occurred in these soils.

This knowledge allowed further refinement of irrigation practices and demonstrates the need to invest in R&D that may not be initially attractive to farmers but helps in understanding the environment and how best to manage farming systems.

Plant Available Water Content (PAWC) is also a critical part of the knowledge irrigation managers must have, and this is now well established for cotton cropping soils across the whole cotton industry. Farmers use in-field measurement, laser leveling, farm drainage plans and farm water reticulation to enhance their supply of irrigation water and to use it efficiently.

According to Roth et al, (2013), whole-farm irrigation efficiency index has improved from 57% to 70% over the decade 2000 to 2010.

Modern Cropping Systems

Productivity of irrigated cropping systems is influenced by cultivar and growing region, and the interaction between the amount of applied nitrogen and phosphorus fertilizer, plant stand, in-crop rainfall and the number of irrigations, season length and days to defoliation (Braunack M.V. (2013).

The fine-tuning of these interacting crop productivity factors requires region-specific research, as was demonstrated by the studies on crop nutrition conducted by Hibberd et al. (1980).

Although most of Australian cotton production is from irrigated production systems, a significant area is planted to raingrown crop each year.

The widespread adoption of reduced and zero tillage production systems, combined with Global Positioning System (GPS) technology which enables “tram-tracking”, has enhanced the productivity of these systems.

Retention of undisturbed crop residue enhances water infiltration from rainfall, increases the storage of soil water, and the use of herbicides in fallow and glyphosate in-crop reduces the need for mechanical cultivation which also better conserves soil water. Yields of 10 bales per hectare are not uncommon in raingrown crops.

Fibre Quality

Australian cotton is exported, mostly to Asia, and Australia is a leading supplier of high quality cotton fibre. Australian cotton is a preferred upland fibre for ring spinning and enjoys a reputation for extremely low contamination.

Typically, Australian cotton has staple length ranging from 29 mm to 32 mm, with a strength of 30GPT. Micronaire ranges between 3.5 and 4.9 depending on seasonal conditions. High Volume Instrument (HVI) Classing has been adopted across the industry.

Extension

Public Sector extension efforts were instrumental in gaining adoption of new technologies and sharing of ideas across the industry in the 1960s and 1970s.

In the 1980s the industry embraced crop consultants and by 1990, almost all farmers employed an insect scout and or an agronomist to ensure their farm was using the best available technology. Crop consultants excelled at providing farmers with individualized crop advice. Corporate farmers employed their own agronomists.

The public sector maintained an extension effort which concentrated on strategic issues of industry importance. A review conducted jointly by CRDC and the first Cotton CRC concluded that both the consultancy role and the publically-funded extension role were essential for the rapid uptake of technology.

In 2012, at the conclusion the Cotton CRCs, CottonInfo was formed to connect cotton growers, consultants, and agronomists with the latest news, information, events and research, and to help the industry achieve best practice. CottonInfo was formed by the three joint venture parties; Cotton Australia, the Cotton Research and Development Corporation and Cotton Seed Distributors Ltd.

CottonInfo has a team of over 20 staff with Regional Development Officers, Technical Specialists and a myBMP team who run the Industry’s Best management Practice Program.

Conclusions

The challenge for the modern Australian cotton industry is to maintain the rate of productivity gain achieved over the last four decades. To achieve this, the Australian cotton industry must continue to embrace RD&E and rapidly adopt new technology.

Outlined below are some of the factors critical to the ongoing development and application of technology within the industry:

1. RD&E professionals feel like they are part of the industry;

2. New ideas welcomed from all sectors:

-

Farmers

-

RD&E professionals

-

Consultants

-

Agribusiness

-

Input Suppliers

-

Marketers

3. The industry maintains a constructive, supportive, and innovative culture, embracing new ideas, respecting one another’s contribution and being prepared to take the risks associated with taking on new technology.

Over the whole period of the modern cotton industry, since the 1970s, cotton industry leaders have nurtured RD&E professionals and the industry has reaped the rewards for doing so.

Bibliography

ABARES: (2015) http://data.daff.gov.au. Agricultural Commodities – 5 no. 2 • June quarter.

Braunack, M. V. (2013), Cotton farming systems in Australia: factors contributing to changed yield and fibre quality. Crop and Pasture Science. 64:834-844.

Constable, G.A. (2004) Research’s contribution to the evolution of the Australian cotton industry, Proceedings of the 4th International Crop Science Congress Brisbane, Australia.

Constable, Greg, Danny Llewellyn, Lewis Wilson and Warwick Stiller. (2011) An industry Transformed: The impact of GM Technology on Australian Cotton Production. Farm Policy Journal 8 No 1. Autumn Quarter.

Cotton Australia (2016) http://cottonaustralia.com.au.

Cunningham Yvette, and Paula Jones, Editors. (2012) Weaving a future for Australia’s cotton catchments and communities. Published by the Cotton Catchments Communities Cooperative Research Centre.

Daly, J.C. and Murray, D.A.H. (1988) Evolution of resistance to pyrethroids in Heliothis armigera (Hubner) (Lepidoptera: Noctuidae) in Australia. Journal of Economic Entomology 81:984-988.Murray D Cotton Conference

Cameron J, and Hearn A B. (1997) Agronomic and economic aspects of water use efficiency in the Australian cotton industry. A report compiled for the Cotton Research and Development Corporation.

Hamilton, W. D. and Hazard, W. H. (1981) Weed Control in the Emerald Irrigation Area. Qld Agric Journal 106:6 482-492.

Hibberd, D. E., Hamilton, W. D. and Soley, N.G. (1980). Nutritional investigations in cotton Emerald Irrigation Area. Proceedings of the Australian Agronomy Conference. Qld Agric College, Lawes.

Monsanto.com (2016): http://Monsanto.com/global/au.

Murray, D., Ingram, B., Lloyd, R., Marshall, J., Thomson, S., Scholz, B. and Rynne, K. (1996). Four years of IPM in raingrown cotton. Proceedings 1996 Australian Cotton Conference, Broadbeach, Queensland.153-157.

Roth, Guy, Graham Harris, Malcolm Gillies, Janelle Montgomery and David Wiggington. (2013) Water-use efficiency an dproductivity trends in Australian irrigated cotton: a review. Crop and Pasture Science 64: 1033-1048.

Silburn M, and Montgomery J (2004) Deep drainage under irrigated cotton in Australia: a review in WATERpak; a guide for irrigation management in cotton. Cotton Research and Development Corporation.

Scott, Kirsten, D, Nicole Lawrence, Corinna L. Lange, Leon j. Scott, Kendle S. Wilkinson, Melissa A. Merritt, Melina Miles, David Murray and Glenn C. Graham. (2005). Assessing Moth Migration and Population Structuring in Helicoverpa armigera (Lepidopera: Noctuidae) at the Regional Scale: Example from the Darling Downs, Australia. Journal of Economic Entomology, 98: 6.

Tennakoon S.B. and S. P. Milroy. (2003). Crop Water Use Efficiency on Irrigated cotton farms; Australia Agricultural Water Management 61:179-194.

USDA (2015) Corn for Grain Yields. http://usdasearch.usda.gov/search

Wilson, Lewis, Sharon Downes, Moazzem Kahn, Mary Whitehouse, Geoff Baker, Paul Grundy, Paul and Susan Maas (2013) IPM in the transgenic era: a review of the challenges from emerging pests in Australian cotton systems. Crop and Pasture Science 64: 737-749.

World Leaders in cotton. (2014) Achievements in Australian cotton research development and extension 2008-2013. Published by the Cotton Research and Development Corporation, August 2014.

Further Reading

Cotton Catchment Communities CRC – Research Outcomes and Innovation (Part1). Crop and Pasture Science Volume 64, Issue 8:2013.

Cotton Catchment Communities CRC – Research Outcomes and Innovation (Part 2). Crop and Pasture Science Volume 64, Issue 11 and 12:2013.

David Hamilton

The Author graduated from the University of Queensland in 1973 with a BAgrSc and commenced his career in the cotton industry when he was appointed as an Extension Agronomist responsible for irrigated crop production in the St George region of Queensland with the Queensland Department of Primary Industries.

Following an initial four years in St George, the author moved to the Emerald region in Central Queensland when cotton production was in its infancy. After a period of study (MS in Agronomy at Texas A&M University) supported by the Australian cotton Industry, he returned to Emerald to continue work as an Extension Agronomist focussed on irrigated and dryland agriculture with a special interest in cotton agronomy.

In 1992, the author was appointed to the Cotton R&D Corporation Board and served successively on boards of the Cotton Cooperative Research Centres form 1994 until 2012.

This paper elaborates on a presentation given to the Ag Institute conference in Perth, August 2015.

The paper does not attempt to review all of the relevant RD&E, but rather touch on the main subjects and relate RD&E activities that have been instrumental in solving challenges for the industry, particularly those activities that the author has been associated with.

Figures

Table 1. History of Australian Cotton Production

Figure 1. Current cotton production areas in Australia.

Figure 2. The Australian Cotton Industry’s Yield Increases 1961 to 2013 compared with the global cotton industry (Source: Cotton R&D Corporation- World Leaders in cotton).

Figure 3. Corn for grain yields, United States. Source: USDA, November 2014.