Plastic-film mulch in Chinese agriculture: Importance and problems

Summary

Plastic-film mulch is widely used to increase the productivity of crops, vegetables and fruit trees in cold and arid or semiarid regions of China.

Use increased from 6000 t, covering 0.12 million ha, in 1982, to 1.2 million t, covering almost 20 million ha, in 2011. The thin (4-8 µm) polyethylene film used in China is slow to degrade, easily damaged, difficult to reuse for a second season and difficult to remove.

Residual plastic in the top 0.3 m soil layer is now estimated to vary from 72 to 260 kg/ha, depending on number of years use, percentage of ground covered and film thickness.

Research results showed that plant growth was affected when residual plastic exceeded 37.5 kg/ha in the soil; the emergence of winter wheat seedlings decreased by 25% and the tiller number decreased by 17%.

Cotton yields were reduced by 4%, 8%, 12% and 19%, respectively when the amount of residual plastic in the soil was 80, 170, 280 and 370 kg/ha.

Use of photo- and bio-degradable plastics is currently considered to be too expensive for agricultural use in China, but we suggest that use of thicker (15 µm) and stronger film that can be reused for two or more years, together with planters that can collect the residual plastic while (planting) sowing, should be developed.

Keywords

plastic residues, soil pollution, yield decline, degradable plastic film, China

1. The application of plastic-film mulch in agriculture

The use of plastic-film mulch is now widespread in agriculture, particularly in cold, arid and semiarid regions of China.

The mulch has numerous functions, including increasing the soil temperature, intensifying sunlight penetration, reducing soil evaporation and maintaining soil water content; also improving fertilizer-use efficiency, soil conservation, and reducing and eliminating weeds (1, 2, 3, 4).

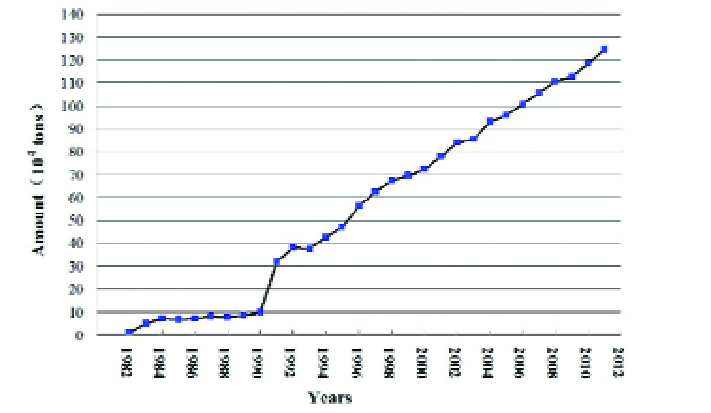

Over the past three decades, the amount of plastic film applied and area covered has increased dramatically from 6000 t in 1982, to 1.2 Mt in 2011, a 200-fold increase (Figure 1) (5).

The area of crops with plastic-film mulching has continued to increase from only 0.12 Mha in 1982, to 4.9 Mha in 1991, 11.0 Mha in 2001 and 19.8 Mha in 2011(6).

Plastic-film mulch is widely applied, from the arid and semiarid regions in north China to the mountainous, cold regions in south China, such as the provinces of Inner Mongolia, Shandong, Henan and Hebei in north China, Xinjiang and Gansu in northwest China, and Sichuan and Yunnan in southwest China.

Shandong, Xinjiang and Sichuan are the leading provinces in the use of plastic-film mulch, using 148,100 t, 121,200 t and 71,000 t, respectively in 2008 (5).

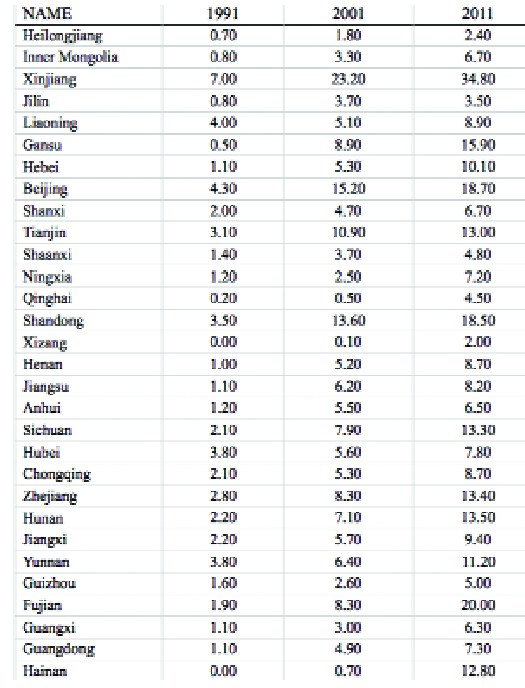

The plastic film utilization intensity index (kg/ha/yr), calculated by dividing the application quantity (kg) of plastic-film mulch by agriculture (ha covered) of the province or city, reflects the use of plastic-film mulch in the region. Xinjiang had the largest utilization intensity of plastic-film mulch with 34.8 kg/ha/yr in 2011 as a result of the special climate and agricultural activities in the region (5, 6). In Xinjiang, irrigation, especially drip irrigation under the plastic film, is widely utilized in agricultural production, resulting in a rapid increase in the quantity of plastic film used. Shanghai and Beijing also have high plastic-film utilization intensity for vegetable and fruit production in the peri-urban and urban areas. The provinces with significant agricultural production like Shandong, Hebei, Henan, Sichuan and Gansu, all had high (above 10 kg/ha/yr) use intensity indexes of plastic film. From 1991 to 2011, the intensity in all the provinces and cities increased by 3-to- 8-fold (Table 1).

Plastic-film mulch has been widely used in the production of grain, cotton, oilseeds, sugar, vegetables, melons, fruit and tobacco, to improve crop yields, save water, enable earlier harvesting, and reduce herbicide and pesticide use (4, 7). The crop with the largest use of plastic-film mulching is maize, especially in arid mountain regions (Figure 2). In 2011 the area of plastic-film mulch for maize and vegetables was about 6.7 Mha, cotton, 3.4 Mha and peanut and tobacco, about 1.0 Mha.

2. Pollution by plastic-film residue

The plastic films used in China are a macromolecule hydrocarbon compound made from polyethylene (PE) by adding antioxidants.

They are of high molecular weight, highly stable and may persist in the soil under natural conditions. The plastic-film residue arising from large-scale use is considered to be a risk factor for sustainable agriculture in China. Over the past three decades about 20 Mt of plastic film have been applied(5), and 2 Mt of plastic-film residue remain in the soil.

The thin (4-8 µm) plastic film is extremely difficult to recycle because of the high labour requirement. Farmers have to harvest the film by hand or with machinery before sowing the subsequent crop (Figure3). In Xinjiang and Gansu, the large quantity of plastic-film residue remaining in the soil has affected agricultural activities and crop growth.

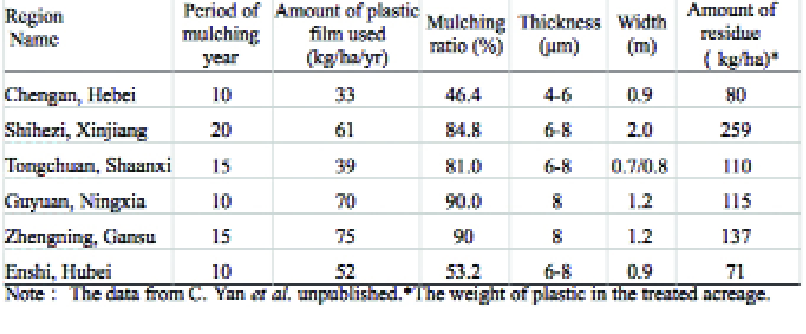

The amount of residual plastic in the soil varies with the number of years of mulching, film thickness, sheet width, and the percentage of soil covered by the film in the treated area (the mulching ratio).

Our results showed that Xinjiang had the maximum film input of 61 kg/ha and that Hebei had the minimum of 33 kg/ha. In Xinjiang, Gansu and Ningxia in northwestern China, the mulching ratio was high, up to 80%, while in the southwest mountain areas and in northern China the mulching ratio was only about 40% (Table 2).

According to the Ministry of Agriculture of China (5), the agricultural residual plastic-film in the 17 provinces averages 60 kg/ha over the 10-year period of application in the 1990s(8).

The average plastic-film residue in farmland soils was 90 to 150 kg/ha, the severest pollution occurred in the cotton fields in Xinjiang with the average residue of 259 kg/ha (Table 2), and with the maximum plastic film residue of 381 kg/ha.

On average, the residual pieces of plastic film in the soil are 1-2500 cm2 in area, with most pieces being 4-25 cm2. The percentage of pieces >25 cm2 is 16% to 25%, the percentage of that from 4-25 cm2 is about 44%-54%, while the pieces <4 cm2 accounts for 21%-40% of the total.

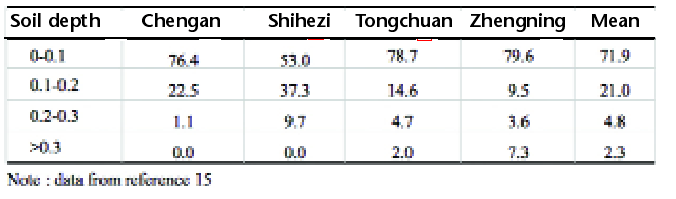

Depending on agricultural activities and usage, the residue exists as flakes, curled pieces or cylindrical and spherical balls distributed horizontally, vertically or at any angle in the soil. 71.9% of the pieces are deposited in 0-0.1 m, 21% in the 0.1-0.2 m, 4.8% in the 0.2-0.3 m and 2.3% below 0.3m soil layer (Table 3) (Figure4).

In general, the number of years of use plastic film was proportional to the depth at which residues were found (9, 10, 11, 12, 13).

The plastic-film residue is considered to be a risk for sustainable agriculture as there are several adverse effects on the soil.

The most important one is that the residue can prevent the penetration and flow of water within the plough layer and surface layer of soil, reducing infiltration and affecting the water absorption of the soil (15, 16, 17, 18, 19, 20).

The plasticizer, diisobutyl phthalate (DIBP), added to the plastic film during the production process is volatile, may diffuse into the mesophyll cells through the stomata of the plant, to damage the chlorophyll and limit its formation(2, 17), and thereby affect plant growth.

When the quantity of plastic-film residue in the soil reached 37.5 kg/ha, the seedling numbers of winter wheat decreased by 25% and the tiller number decreased by 17%.

Plastic-film residue may also limit the growth of the root systems of maize, eggplant, cabbage and peanut.

Cotton yields were reduced by 4%, 8%, 12% and 19%, respectively when the amount of residual plastic in the soil was 80, 170, 280 and 370 kg/ha respectively (15, 16).

Plastic-film residue not only affects the soil and growth and development of crops, resulting in a decrease in crop yield, but has other adverse effects.

One is the death of cattle following ingestion of plastic film mixed with the stover used as cattle feed, while another is the aesthetic pollution from plastic-film residue deposited by roadsides, in ditches and along fences.

It also binds around the wheels of a seeder or the teeth of a plough, and hinders the cultivation operations (Figure 5)(9, 10, 18).

3. Reducing plastic-film residue pollution

3.1 Use less plastic film

To save and reduce the input of plastic film in the field, a technique has been developed, which is called the multipurpose plastic- film technique, that is, the use of plastic-film mulch of medium thickness (15 µm), increased toughness, and high resistance to damage.

After harvesting, it can be collected and reused for a subsequent crop or crops, which not only reduces the use of plastic film, but also saves time and labour and protects the environment.

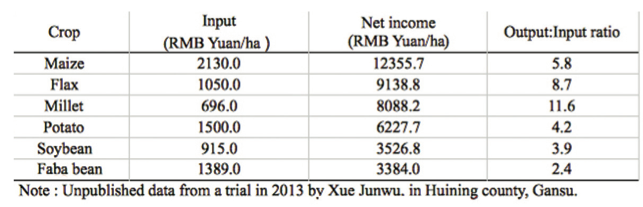

In Gansu during 2013, the technique was shown to reduce the mulching ratio from 80%-100% to 50%-70% while maintaining a high crop yield (Table 4).

3.2 Use of degradable plastic film Photodegradable and biodegradable plastic to replace PE plastic film (21) would have the advantage of reducing residue pollution (22).

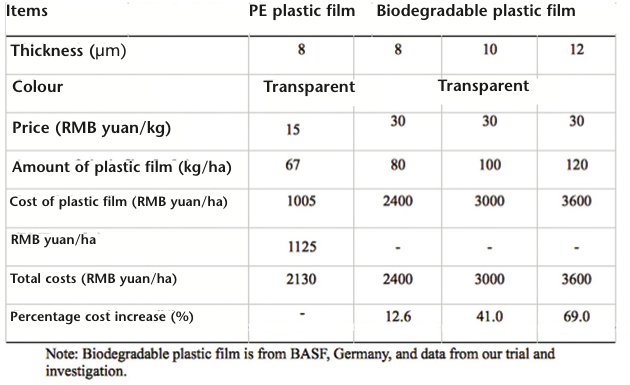

Cost of degradable plastic film is the main obstacle to its use in China. An economic assessment of biodegradable and PE plastic film for cotton production showed that the price of biodegradable film was double, although the total input costs of biodegradable film with different thicknesses increased by only 12%, 41% and 69%, respectively, because of exclusion of the cost of collecting biodegradable residues (14) (Table 5).

Considering the environmental effect, biodegradable film has a great potential for agricultural application in the future.

3.3 Mechanization of residual plastic recycling technology In developed countries, plastic film is generally used in vegetable, fruit and other cash crops.

In these countries, the plastic film has 15 μm thickness, and is easy to reclaim by machine. In China, the plastic film mulch for agricultural use is very thin with only half of thickness of that used in developed countries, fragile and easily damaged, and thus not easily reclaimed by machine.

Nevertheless, several kinds of reclaiming machines, such as roller and rake types are available and highly efficient in reclaiming plastic residues. We propose that a planter with a facility for reclaiming plastic residue from the previous crop is the key to future development (23, 24, 25).

4. Conclusions The continuous use of thin stable PE plastic-film mulch for improving crop production in cold and dry regions of China has led to large quantities of plastic residue building up in the soil.

It has begun to reduce crop growth and yields, particularly in cotton which has the longest term use among crops. For sustainable agriculture, the continuous use of plastic-film mulch needs to be reduced in the future.

Degradable plastic, thicker and stronger plastic film for multiple-year use, a reduction in the mulching ratio and the use of cultivators/seeding equipment that can pick up plastic residue are recommended for reducing plastic pollution. These techniques need to be explored.

Acknowledgements

We thank two reviewers and Dr. David Frape for their valuable suggestions and comments, which led to substantial improvements of this paper.

This study was partially supported by the Chinese National Scientific Foundation (No. 31370522), the 12th five-year plan of National Key Technologies R&D Program (No. 2012BAD09B01) and “948” project from Ministry of Agriculture (2014-Z6). Dr. He Wenqing is corresponding author.

References

1. Li Fengmin, Wang Jun, Xu Jinzhang, Xu Huilian (2004) Productivity and soil response to plastic film mulching durations for spring wheat on entisols in the semiarid Loess Plateau of China. Soil and Tillage Research 78, 9-20.

2. Yan Changrong, He Wenqing, Mei Xurong (2010) Agricultural application of plastic film and its residue pollution prevention . Beijing: Science Press. pp. 76~86.

3. Wang Hanbo, Gong Daozhi, Mei Xurong, Hao Weiping (2012) Dynamics comparison of rain-fed spring maize growth and evapotranspiration in plastic mulching and un- mulching fields. Transactions of the Chinese Society of Agricultural Engineering 28 (22), 88-94.

4. Gan Yantai, Siddique K H M, Turner N C, Li X-G, Niu J-Y, Yang C, Liu L, Chai Q (2013) Ridge-furrow mulching systems - an innovative approach for boosting crop productivity in semiarid rain-fed environments. Advances in Agronomy 118, 429- 476.

5. Ministry of Agriculture P. R. China. China agricultural statistics yearbook, Beijing: Chinese Agricultural Press.

6. Rural Society Investigation Department of National Statistical Bureau. China Rural Statistics Yearbook. Beijing: China Statistics Press, 2002, 2012.

7. Scarascia-Mugnozza G, Sica C, Russo G (2011) Plastic materials in European agriculture: Actual use and perspectives. Journal of Agricultural Engineering 42 (3), 15-28.

8. Wang Xiaofang, Shen Maoxiang (1998) Farmland plastic film-Hope and dawn of Chinese agricultural development. Countryside Science and Technology Department of Science of China.

9. Yan Changrong, Mei Xurong, He Wenqing, Zheng Shenhua ( 2006 ) Present situation of residue pollution of mulching plastic film and controlling measures. Transactions of the Chinese Society of Agricultural Engineering 22 (11), 269-272.

10. Yan Changrong, Wang Xujian, He Wenqing, Ma Hui, Cao Silin, Zhu G (2008) Study on the residue of plastic film in cotton field in Shihezi, Xinjiang. Acta Ecologica Sinica 28, 3470-3484.

11. Ma Hui, Mei Xurong, Yan Changrong, He Wenqing , Li Kang ( 2008 ) The residue of mulching plastic film of cotton field in North China. Journal of Agro-Environment Science 23, 570-573.

12. He Wenqing, Yan Changrong, Zhao Caixia, Chang Ruifu, Liu Qin, Liu Shuang (2009) Study on the pollution by plastic mulch film and its countermeasures in China. Journal of Agro- Environment Science 28, 533-538.

13. He Wenqing, Yan Changrong, Liu Shuang, Chang Ruifu, Wan X, Cao Silin, Liu Qin (2009) The use of plastic mulch film in typical cotton planting regions and the associated environmental pollution. Journal of Agro-Environment Science 28, 1618-1622.

14. Zhao Caixia, He Wenqing, Liu Shuang, Yan Changrong , Cao Silin (2011) Degradation of biodegradable plastic mulch film and its effect on the yield of cotton in Xinjiang region, China. Journal of Agro-Environment Science 30, 1616-1621.

15. Zhao Surong, Zhang Shurong, Xu Xia, Xu Lichao, Zhang Donghe, Zhang Xinmin , Wang Jinfeng, Xu Ligong , Qi Ying ( 1998 ) Study on the agricultural plastic sheeting residue pollution. Agro-environment and Development 3, 7-10.

16. Cheng Guihua, Liu Xiaoyang, Liu Yuanjun, Jin Weixu, Mu Luming, Yan Zhonghui (1991) Study on permissible value of plastic residual piece in field soil. Soil and Fertilizer 5, 27-30.

17. Nan Dianjie, Xie Honge, Gao Liangsheng, Zhang Dongmei , Zhao Haizhen, Ren Pinghe , Chai Shiwei (1996) Study of the influence of the residue film on soil and cotton growth in the cotton fields. Acta Gossypii Sinica (now Cotton Science) 8 (1), 50-54.

18. Gao Qinghai, Lu Xiaomin, (2011) Effects of plastic film residue on morphology and physiological characteristics of tomato seedlings. Journal of Tropical and Subtropical Botany 19, 425-429.

19. Chang Ruifu, Yan Changrong (2012) Research report on overall current situation on agricultural plastics residuals pollution and its countermeasures. Beijing: China Agricultural Science and Technology Press, pp. 13-15, 41.

20. Lu Shengzeng, Zhou Zhenfeng, Yan xishi (2013) Environmental problems and control ways of plastic film in agricultural production. Applied Mechanics and Materials 295, 2187-2190.

21. Ammala A, Bateman S, Dean K, Petinakis E, Sangwan P, Wong S, Leong KH (2011). An overview of degradable and biodegradable polyolefins. Progress in Polymer Science, 36(8), 1015-1049.

22. Kyrikou I, Briassoulis D (2007) Biodegradation of agricultural plastic films: a critical review. Journal of Polymers and the Environment, 15(2), 125-150.

23. Cao Silin, Wang Xujian (2008) The research status of plastic film residual pollution control and the patent strategy. Agricultural Machinery 20, 77-78.

24. Cao Silin, Wang Xujian, Shen Congju, Lu Bing (2000) Patent analysis on mechanization technology of retrieving the used plastic film. Chinese Agricultural Mechanization 4, 48-50.

25. Cao Silin, Wang Xujian, Wang Min, He Yichuan, Liu Yun (2012) Design and experimental research on 1LZ series combined tillage machine. Acta Agriculturae Boreali- Occidentalis Sinica. 21, 202-206.

Download pdfFigures

Figure 1. The amount of plastic-film mulch used in Chinese agriculture from 1982 to 2011.

Figure 2. Hillsides in rainfed areas covered with plastic-film mulch (Photo by Zhang Yajian, 2012)

Table 1. The plastic-film utilization intensity index (kg/ha/yr) of Chinese provinces and cities.

Figure 3. Removing plastic-film residue in Gansu and Xinjiang (Photo by Yan Changrong, 2008).

Table 2. The use of plastic film and the residues of plastic in five representative regions

Figure 4. Plastic-film residue pollution in crop fields in Xinjiang (Photos by He Wenqing (Left, 2006) and Zheng Jiaming (Right, 2014).

Table 3. The plastic-film residues in soil profile (depth, m) after 10-20 years used in four representative regions (%)

Figure 5. Some side effects of plastic residues pollution in China

Table 4. The economic analysis of Multipurpose plastic-film mulch technique for crops in Gansu

Table 5. Annual economic assessment of biodegradable and PE plastic film in cotton production